Radiator Components

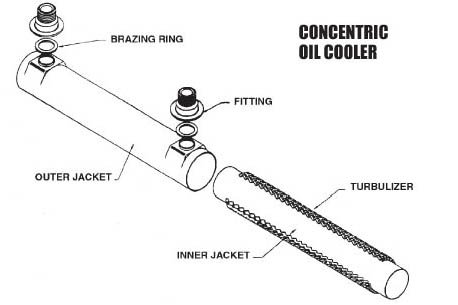

Concentric Oil Cooler

Product Description

Sunraj Industries exports Concentric Oil Cooler made up of Copper and Brass.

Features:

1) Various types for different cars

2) Material: copper / Brass

3) Light-weight, high-efficiency and reliable performance

4) Various specifications according to customers’ requirements

Sunraj manufacture Concentric Oil Coolers for various models of cars according to your specification.

- BMW

- CHRYSLER

- DATSUN

- FORD

- GENERAL MOTORS

- HONDA

- MAZDA

- MERCEDES

- NISSAN

- RENAULT

- SUBARU

- TOYOTA

- AMERICAN MOTORS

Technical Drawing :

Drain Cock

Product Description

Sunraj Industries exports Drain Cocks made up of Brass-to-Brass and Nylon-to-Brass. Both the Drain Cocks are used for same application in different types of Radiators. Brass-to-Brass Drain Cock is generally used for trucks and generators and Nylon-to-Brass are generally used for car radiators.

Inlet Outlet Pipes

Product Description

Sunraj Industries exports Inlet Outlet Pipes made up of Brass, Copper, Aluminium, Mildsteel(MS). These inlet outlet pipes are manufacture as per customer design. Sunraj Industries expertise in making inlet outlet pipes in bigger diameter in single piece.

Radiator Brass Tanks

Product Description

Sunraj Industries exports wide range of Radiator Brass Tanks for various Trucks and Cars. These are stronger, lighter in weight and corrosion resistance. Sunraj can manufacture Radiator Tanks as per customer drawing and requirement.

Sunraj exports Raditor Brass Tanks for various models of cars according to your specification.

- BMW

- CHRYSLER

- DATSUN

- FORD

- GENERAL MOTORS

- HONDA

- MAZDA

- MERCEDES

- NISSAN

- RENAULT

- SUBARU

- TOYOTA

- AMERICAN MOTORS

Radiator Filler Neck

Product Description

Sunraj Industries is one of the largest exporters of Radiator Filler Neck, and manufacture Micro, Mini, Small, and Medium size caps for various radiator applications. Radiator Filler Neck are manufacture in Brass and Aluminium for Copper /Brass Radiators and Aluminium Radiators.

Specification:

- Brass thickness as per customer’s requirement.

- Overflow pipe dia. and length as per customer’s requirement.

Product Size:

| Size | Diameter |

| Micro Cap | 41 mm Dia. |

| Mini Cap | 43 mm Dia. |

| Small Cap | 57 mm Dia. |

| Medium Cap | 68.5 mm Dia. |

Technical Details of Radiator Filler Necks:

| Nominal Pressure Rating kPa | Nominal Pressure Rating psi | F mm | G mm | H mm | I mm | J mm | K mm | L mm | M mm | N Nom mm | P Min mm | R mm |

| Mini | ||||||||||||

| 83-110 | 12-16 | 38.40–39.00 | 12.19–13.21 | 42.80–43.20 | 31.10–31.7 | 5.08–5.33 | 22.4–22.7 | 10.45–10.7 | 12.43–12.68 | 19.7 | 12.0 | 4.70–5.0 |

| 97–124 | 14-18 | 38.40–39.00 | 12.19–13.21 | 42.80–43.20 | 31.10–31.7 | 5.08–5.33 | 22.4–22.7 | 10.45–10.7 | 12.43–12.68 | 19.7 | 12.0 | 4.70–5.0 |

| Small | ||||||||||||

| 21–34 | 3-5 | 49.78–50.29 | 12.19–13.21 | 56.39–56.77 | 41.15–41.53 | 5.46–5.72 | 30.7–31.0 | 13.75–14.0 | 16.05–16.3 | 28.3 | 12.45 | 4.90–5.16 |

| 41–55 | 6-8 | 49.78–50.29 | 15.24–16.26 | 56.39–56.77 | 41.15–41.53 | 5.46–5.72 | 30.7–31.0 | 13.75–14.0 | 16.05–16.3 | 28.3 | 15.75 | 4.90–5.16 |

| 62–76 | 9-11 | 49.78–50.29 | 15.24–16.26 | 56.39–56.77 | 41.15–41.53 | 5.46–5.72 | 30.7–31.0 | 13.75–14.0 | 16.05–16.3 | 28.3 | 15.75 | 4.90–5.16 |

| 83–110 | 12-16 | 49.78–50.29 | 21.84–22.86 | 56.39–56.77 | 41.15–41.53 | 5.46–5.72 | 30.7–31.0 | 13.75–14.0 | 16.05–16.3 | 28.3 | 22.34 | 4.90–5.16 |

| 97–124 | 14-18 | 49.78–50.29 | 21.84–22.86 | 56.39–56.77 | 41.15–41.53 | 5.46–5.72 | 30.7–31.0 | 13.75–14.0 | 16.05–16.3 | 28.3 | 22.35 | 4.90–5.16 |

| Medium | ||||||||||||

| 21–34 | 3-5 | 61.72–62.23 | 12.70–13.72 | 68.33–68.71 | 54.10–54.48 | 5.46–5.72 | – | 13.05–13.3 | 15.35–15.6 | 40.70 | 10.67 | 4.90–5.16 |

| 41–55 | 6-8 | 61.72–62.23 | 18.29–19.30 | 68.33–68.71 | 54.10–54.48 | 5.46–5.72 | – | 13.05–13.3 | 15.35–15.6 | 40.70 | 17.02 | 4.90–5.16 |

| 62–76 | 9-11 | 61.72–62.23 | 18.29–19.30 | 68.33–68.71 | 54.10–54.48 | 5.46–5.72 | – | 13.05–13.3 | 15.35–15.6 | 40.70 | 17.02 | 4.90–5.16 |

| 83–110 | 12-16 | 61.72–62.23 | 22.61–23.11 | 68.33–68.71 | 54.10–54.48 | 5.46–5.72 | – | 13.05–13.3 | 15.35–15.6 | 40.70 | 22.35 | 4.90–5.16 |

Radiator Pressure Cap

Product Description

Sunraj Industries exports Radiator Pressure Caps of various sizes like Micro, Mini, Small and Medium of various pressures rating as per customer requirements.

Radiator Caps are pretty simple in appearance, but looks can be deceiving. Each part of the cap performs a special function:

Application for Naval Brass Plate/Sheet and Circles :

- Heat Exchange Baffles and Tube Sheets.

- Marine Hardware.

- Under the top of the cap is a spring disc diaphragm (and upper sealing gasket on closed system caps) that seals against the top of the radiator filler neck and provides friction to keep the cap from working loose.

- The big spring is what maintains pressure on the coolant. The spring holds the pressure valve and lower sealing gasket against the base of the radiator filler neck to raise the coolant’s boiling temperature and to keep it from escaping. When the pressure rating of the spring is exceeded, the pressure valve opens venting coolant into the overflow reservoir.

- The lower sealing gasket is what keeps the coolant where it belongs. This gasket must be in excellent condition for the cap to seal tightly and do its job. If cracked, age-hardened or damaged, pressure and coolant can escape, allowing the engine to overheat.

- A vacuum valve in the bottom of the cap allows coolant to be siphoned back into the radiator when the engine cools down. This keeps the radiator full, which helps prevent overheating and the formation of steam pockets. On many domestic passenger car applications with pressure vent-type caps, the vacuum valve also vents pressure when the cooling system is under light load. This allows the cooling system to operate at atmospheric pressure until the expansion of coolant and the creation of pressure in the system closes the valve.

Product Range:

Pressure Cap Pressure Specification Size 13 PSI (0.9 Kg/cm2)

16 PSI (1.1 Kg/cm2)– Micro Cap

[For 41 mm dia Filler Neck]13 PSI (0.9 Kg/cm2)

16 PSI (1.1 Kg/cm2)

7 PSI (0.5 Kg/cm2)*SAE -J-164

(Reaffirmed FEB97)Mini Cap

[For 43 mm dia. Filler Neck]7 PSI (0.5 Kg/cm2)

11 PSI (0.8 Kg/cm2)

13 PSI (0.9 Kg/cm2)

14.2 PSI (1.0 Kg/cm2)

16 PSI (1.1 Kg/cm2)SAE -J-164

(Reaffirmed FEB97)

&

IS – 12996Small Cap

[For 57 mm dia. Filler Neck]7 PSI (0.5 Kg/cm2)* – Medium Cap

[For 68.5 mm dia. Filler Neck]

Pressure Cap Testing Process:

- Main valve opening.

- Vacuum valve opening.

- Top seal testing.

- Assembly fitting.

- Spot welding strength.

- Spring test.

a. Spring load test

b. Helical spring endurance test.

c. Vent valve spring endurance

d. Plant spring endurance test.

7. Torque test for assembly setting.

8. Open pressure difference test.

9. Pressure opening test.

10. Valve disk riveting.

11. Salt spray test of cap cover.

12. Chemical analysis.

Technical Details of Radiator Pressure Cap:

Nominal Pressure Rating

kPaNominal Pressure Rating

psiA

mmB

mmC

mmD

mmE

Max

mmMini 83-110 12–16 10.70–11.70 11.20–12.00 39.2–40.0 43.43–43.80 66.0 97–124 14–18 10.70–11.70 11.20–12.00 39.2–40.0 43.43–43.80 66.0 Small 21–34 3–5 10.92–11.94 14.73–15.62 50.80–52.32 57.15–57.79 80.26 41–55 6–8 14.22–15.24 14.73–15.62 50.80–52.32 57.15–57.79 80.26 62–76 9–11 14.22–15.24 14.73–15.62 50.80–52.32 57.15–57.79 80.26 83–110 12-16 20.83–21.84 14.73–15.62 50.80–52.32 57.15–57.79 80.26 97–124 14-18 20.83–21.84 14.73–15.62 50.80–52.32 57.15–57.79 80.26 Medium 21–34 3–5 9.14–10.16 13.72–14.61 62.74–64.26 69.34–69.98 92.71 41–55 6–8 15.49–16.51 13.72–14.61 62.74–64.26 69.34–69.98 92.71 62–76 9–11 15.49–16.51 13.72–14.61 62.74–64.25 69.34–69.98 92.71 83–110 12–16 20.83–21.84 13.72–14.61 62.74–64.25 69.34–69.98 92.71

Radiator Side Brackets

Product Description

Sunraj Industries export qualitative Radiator Side Brackets for various Radiators. These are manufacture in Mild steel and stainless steel, as per requirements from customers. These brackets are manufactured in adherence with the industry set quality parameters employing latest tool and equipment.

These are manufacture by latest CNC Bending and Punching machines.

Features:

- Light weight

- High performance

- Long durability

- Robust and flexibility design

- Ease of maintenance

Sunraj exports Radiator Side Brackets for various models of cars according to your specification.

- BMW

- CHRYSLER

- DATSUN

- FORD

- GENERAL MOTORS

- HONDA

- MAZDA

- MERCEDES

- NISSAN

- RENAULT

- SUBARU

- TOYOTA

- AMERICAN MOTORS